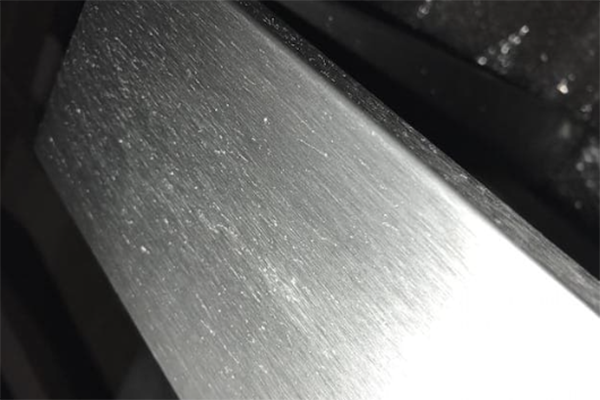

Polishing aluminum to a mirror shine is a labor of love, revealing a brilliant, almost liquid metal finish that’s second to none. However, leaving that beautiful surface as bare aluminum is an invitation for dullness and corrosion. A high-quality clear coat is the essential final step to protect your hard work. As someone whose life’s work revolves around the properties of aluminum—specifically in creating high-performance aluminum pastes for the construction industry—I’ve developed a deep respect for this versatile metal. This article is your comprehensive guide, drawing from both hands-on experience and industrial knowledge, to help you understand the nuances of applying a clear coating to polished aluminum, ensuring your project stays protected and looks fantastic for years to come. We will explore the best methods, from clear powder coat to liquid applications, and detail the critical preparation steps that make all the difference.

Why Should You Clear Coat Polished Aluminum in the First Place?

The primary reason to apply a protective coat to polished aluminum is to combat nature. Raw aluminum, especially when polished, is highly reactive to the oxygen in the air. This reaction, called oxidation, forms a thin, hard, and cloudy layer of aluminum oxide on the surface. While this oxide layer does offer some minimal protection, it completely ruins the mirror shine you worked so hard to achieve. Within weeks, or even days in a humid environment, your brilliant polish will turn into a hazy, milky mess. A clear coat acts as an impermeable barrier between the metal and the elements.

This protective coating does more than just stop oxidation. It shields the soft aluminum from a variety of environmental hazards:

- Moisture and Salt: For parts like a polished aluminum wheel, exposure to road salt and water can cause severe corrosion and pitting. A good clear coat prevents this.

- Chemicals: Engine components or wheels can be exposed to oils, fuels, and harsh cleaning agents that can stain and etch bare aluminum.

- Minor Abrasions: A durable coating provides a defense against a minor scratch or scuff that would otherwise mar the delicate polish.

Ultimately, a clear coat preserves your effort. Without it, you are committing to a routine of constant re-polishing to keep the surface shiny. By applying a quality clear finish, you lock in that perfect polish and transform a high-maintenance showpiece into a durable, low-maintenance asset.

What Are the Main Options for a Clear Coating on Aluminum?

When you decide to protect your polished aluminum, you essentially have two mainstream choices for a clear coating: a traditional liquid clear coat or a modern clear powder coat. Each has distinct advantages and is suited for different applications and skill levels. Understanding these differences is the first step toward making an informed decision.

A liquid clear coat, often a two-part (2K) urethane, is the same type of coating used on cars from the factory. It’s sprayed on as a liquid and cures either by air-drying or with low heat. This method offers a brilliant, high-gloss finish and has the advantage of being something a skilled DIYer can apply with the right equipment. However, it’s less durable than powder coating and more susceptible to chipping and chemical damage. A clear powder coat, on the other hand, involves spraying a dry polymer powder onto the part, which is then heated in an oven. The powder melts, flows into a smooth layer, and cures into a hard, plastic-like shell. This process creates an exceptionally tough and long-lasting finish.

Here’s a quick comparison:

| Feature | Liquid Clear Coat (2K Urethane) | Clear Powder Coat |

|---|---|---|

| Durability | Good | Excellent |

| Appearance | High gloss, can achieve a "wet look" | High gloss, but can slightly mute the polish |

| Application | Can be done with a spray gun | Requires professional electrostatic gun and curing oven |

| Chemical Resistance | Moderate | Excellent |

| Cost | Lower material cost, can be DIY | Higher cost, requires professional service |

| Repairability | Can be spot repaired and blended | Cannot be spot repaired; requires full strip and re-coat |

Is a Clear Powder Coat the Best Choice for Polished Aluminum?

For maximum durability, a clear powder coat is often considered the superior option for coating aluminum parts, especially for high-wear items like a set of wheels. The thermal bonding process creates a coating that is significantly thicker, harder, and more resilient than any liquid paint. It’s highly resistant to chipping, scratching, and the damaging effects of UV light and chemicals. If you’re looking for a "set it and forget it" solution for your polished aluminum wheels, powder coating is hard to beat. The resulting powder coated surface is incredibly easy to clean and maintain.

However, there is a crucial trade-off to consider: the impact on the final look. The process of applying a clear powder coat on polished aluminum can sometimes slightly diminish the "bling" of a perfect mirror polish. The heat required for curing (typically 375-400°F or 190-200°C) and the thickness of the powder coat itself can give the finish a look of being "encased in plastic" and can sometimes reduce the sharpness of the reflection. While high-quality powders minimize this effect, it’s a point frequently discussed in any automotive forum. For a 100-point show car where absolute reflective brilliance is prioritized over all-weather durability, a high-end liquid clear coat might be preferable. For a daily driver or parts exposed to harsh conditions, the robustness of a clear powdercoat is the wiser choice.

How Do You Properly Prepare Polished Aluminum for a Clear Coat?

As a factory owner, I can tell you that in any coating process, success is 99% preparation. This is especially true when applying a clear coat to polished aluminum. The ultra-smooth, non-porous surface of a mirror polish is notoriously difficult for a coating to grab onto. Proper preparation is the only way to ensure strong adhesion and a flawless finish. Rushing this stage will guarantee that your coat will peel, flake, or bubble.

Here is a step-by-step guide to perfect preparation:

- The Final Polish: Get the aluminum to your desired level of shine. Any remaining haze or fine scratches will be permanently locked under the clear coat. Your last polish step should use a high-quality compound and a clean, soft cloth.

- Meticulous Degreasing: This is the most critical step. The surface must be surgically clean and free of all polishing compounds, waxes, and finger oils. Wipe the part down thoroughly with a lint-free cloth and a solvent that leaves no residue, such as isopropyl alcohol (IPA) or a dedicated pre-paint degreaser. Wear nitrile gloves from this point forward—the oils from your skin can ruin adhesion.

- Outgassing (for Powder Coating): Cast aluminum parts, like many aftermarket wheels, are porous and trap microscopic pockets of air and oils. When heated in a curing oven, these gasses expand and escape, creating tiny bubbles or pinholes in the powder coat. To prevent this, a professional powder coater will pre-bake the part at a temperature slightly higher than the curing temperature. This forces the trapped gasses out before the clear powder is applied.

- Tack Cloth: Immediately before applying the coating, go over the entire surface one last time with a tack cloth to pick up any remaining dust or lint. The part is now ready for its clear coat.

What Can Go Wrong When Applying a Clear Coat to Polished Aluminum?

Even with careful planning, issues can arise. Understanding these common problems can help you troubleshoot or, better yet, avoid them entirely. In many online forum discussions, users report failures that almost always trace back to a flaw in preparation or application. The main culprit is a loss of adhesion, where the clear coat simply doesn’t stick to the slick, polished aluminum surface. This can manifest as peeling, especially at the edges, or a cloudy appearance under the coating. This is almost always caused by inadequate degreasing.

Another common pain point, particularly with clear powdercoating, is outgassing. If a cast aluminum wheel isn’t properly pre-baked, the escaping gasses will create tiny pinholes or a rough texture in the final finish. This is why choosing a powder coater with specific experience in coating polished aluminum is so important. They will know this crucial step is non-negotiable. Using a low-quality powder can also lead to problems, such as yellowing over time with UV exposure or a "milky" or opaque appearance that obscures the polish you worked to perfect. A quality clear powder should be crystal clear and formulated for long-term UV stability.

Finally, be aware of chemical reactions. Some aggressive wheel cleaners can damage a liquid clear coat over time, causing it to stain or soften. A fully cured powder coat offers much better protection, but it’s still wise to use pH-neutral cleaners. Any flaw, from a tiny piece of lint to a subtle fingerprint, will be magnified under the glossy clear coating, so an obsession with cleanliness before application cannot be overstated.

Can You Polish an Already Powder Coated Aluminum Surface?

This is a common question, and the answer is generally no, not in the traditional sense. You cannot take an abrasive compound and a buffer to a powder coated surface to remove a deep scratch or enhance its shine the way you would with automotive paint. The powder coated finish is a thermoplastic or thermoset layer; it’s essentially a thin layer of plastic. Aggressive polishing will simply abrade, haze, and destroy the finish.

What you can do is treat it like a car’s clear coat for maintenance purposes. For very light surface scuffs or swirl marks, you might be able to use a very fine finishing polish and a soft foam pad on a machine polisher, but this should be approached with extreme caution. The primary way to maintain a powder coated surface is through cleaning and protection. You can clean it with gentle automotive soap and water, and then apply a high-quality carnauba wax or a modern synthetic paint sealant. This will fill in microscopic imperfections, enhance the gloss, and add a sacrificial layer of protection, making your coated aluminum parts even easier to clean.

How Does the Aluminum Alloy Itself Affect the Coating Process?

From my perspective in the industrial aluminum sector, this is a topic that is often overlooked. Not all aluminum is created equal, and the specific alloy and manufacturing process of your part can significantly impact the coating results. The main distinction is between cast aluminum and forged or billet aluminum. Cast parts, common for OEM and replica wheels, are made by pouring molten aluminium into a mold. This process can leave microscopic porosity within the metal. This porosity is what makes cast aluminum so susceptible to the outgassing issues mentioned earlier. It’s a challenge we understand well, as controlling gas generation is the entire purpose of our Aluminium pastes for aerated concrete.

Forged or billet aluminum parts, on the other hand, are created from a solid block of metal that has been compressed under extreme pressure. This results in a much denser, stronger, and non-porous material. Coating a polished part made from forged aluminum is generally easier because outgassing is a non-issue. The smooth, solid substrate provides an excellent surface for a coat to adhere to, assuming it is prepped correctly. When you’re seeking a coating, especially a powder coat, it’s helpful to know what your part is made of. An experienced coater will adjust their process accordingly, but your own knowledge allows you to have a more informed conversation about achieving the best possible result for your specific aluminum wheel or component.

What’s the Difference Between Clear Coat, Anodizing, and Polishing Alone?

When deciding on a finish for an aluminum part, it’s useful to understand all the options. Polishing, clear coating, and anodizing are three distinct approaches with very different outcomes in terms of look, feel, and protection. Choosing the right one depends entirely on your goals for the part. Polishing alone gives you the brightest possible, raw metallic shine, but offers zero protection from oxidation. It’s a high-maintenance choice suitable only for showpieces that are stored in a controlled environment.

Anodizing is an electrochemical process that creates a very hard, controlled oxide layer on the surface of the aluminum. It’s not a coating that sits on top; it’s an integral part of the metal itself. This makes it incredibly durable and resistant to a scratch. However, anodizing typically results in a matte or satin finish, not a bright polish. While clear anodizing exists, it will not preserve a mirror-like shine. A clear coat, whether liquid or powder, is the only method that encapsulates and protects a true mirror polish. It is a barrier coating that sits entirely on top of the aluminum substrate.

Here is a simple breakdown of the trade-offs:

| Feature | Polished Only | Clear Coat (Paint/Powder) | Anodizing |

|---|---|---|---|

| Look | Brightest mirror shiny finish |

Slightly less bright, high gloss |

Matte or satin, can be colored |

| Protection | None | Excellent barrier coating |

Excellent controlled oxidation |

| Maintenance | Frequent polish required |

Easy cleaning, occasional waxing | Very low, just cleaning |

| Repair | Easy to re-polish a scratch |

Difficult; requires full strip and re-coat |

Cannot be spot-repaired |

=

How Do You Maintain Your Clear Coated Aluminum for Maximum Longevity?

Once your polished aluminum parts have a beautiful, durable clear coat, proper maintenance is simple but essential for keeping them looking new. The goal is to clean the surface without damaging the protective coat. The single most important rule is to avoid harsh, acidic, or highly alkaline cleaners. Many heavy-duty, touchless wheel cleaners are highly caustic and can eat through or stain a clear coat over time. Always opt for a pH-neutral automotive shampoo.

Use the "two-bucket" method for washing: one bucket with soapy water and one with plain water for rinsing your wash mitt. This prevents dragging dirt and grit back across the finish, which can cause swirl marks. Use a soft wash mitt or a gentle brush, never a stiff-bristled brush that could scratch the coating. After washing and drying, applying a layer of protection is highly recommended. A quality carnauba wax or a modern polymer or ceramic sealant will add extra gloss and create a hydrophobic, slick surface that repels water and dirt. This protective sealer also provides an additional barrier against UV rays, further preventing any potential yellowing and preserving the integrity of the coat. This level of care ensures longevity, much like how proper installation and handling preserves the performance of building materials like ALC Wallboard.

Finding the Right Professional: What Questions Should You Ask Your Powder Coater?

Choosing the right shop to entrust with your polished aluminum parts is critical. Not all powder coating businesses have the specific experience required to successfully clear coat polished aluminum. A general-purpose powder coater who primarily works on industrial steel parts may not understand the finesse required. As a B2B business owner who vets suppliers for materials like AAC Block, I know that asking the right questions upfront saves a lot of headaches later.

Before you hand over your parts and your money, treat it like an interview. Here is a checklist of questions you should ask a potential powder coater:

- "Can I see examples of your work on polished aluminum?" A picture is worth a thousand words. Ask to see physical examples if possible, not just photos. Look at the clarity and smoothness of the finish.

- "What is your exact preparation process for polished parts?" Listen for keywords like "multi-stage degreasing," "lint-free wipes," and most importantly, "pre-bake" or "outgassing cycle." If they don’t mention outgassing cast aluminum, they may not be the right choice.

- "What specific clear powder do you use?" Ask for the brand and product name. You can then research it to ensure it is a high-quality, non-yellowing, UV-stable polyester or super-durable powder designed for exterior applications.

- "How do you handle the parts to avoid contamination?" They should confirm they use gloves at all times after the final cleaning and have a clean, dedicated space for coating.

- "What is your policy if there are flaws like bubbles or peeling?" A reputable shop will stand by their work and offer to re-do the job if the flaw is due to their process.

Taking the time to find a true specialist in clear powdercoating will be the best investment you can make in the final outcome of your project.

Key Takeaways

Protecting your polished aluminum is a rewarding final step that combines aesthetics with durability. To ensure your project is a success, remember these crucial points:

- Preparation is paramount. A surgically clean, oil-free surface is non-negotiable for proper adhesion of any clear coat.

- Choose your coating wisely. A clear powder coat offers unmatched durability, ideal for wheels and high-wear parts, while a high-quality liquid 2K clear coat can provide a slightly more brilliant shine.

- Understand your material. Cast aluminum requires a special outgassing pre-bake before powder coating to prevent bubbles in the finish.

- Vet your professional. If you choose powdercoating, select a shop with specific, demonstrable experience in finishing polished aluminum. Ask them about their prep process.

- Maintain with care. Use gentle, pH-neutral soaps and protect your new finish with a quality wax or sealant to ensure it lasts for years.

Understanding the unique properties of aluminum and how to protect it is key to a lasting, beautiful finish. For those of us in the construction and materials industry, this same principle applies on a larger scale. To see how we leverage the power of aluminum in innovative building materials, feel free to explore our work at the BTZmoc factory.

Post time: 8 月-14-2025