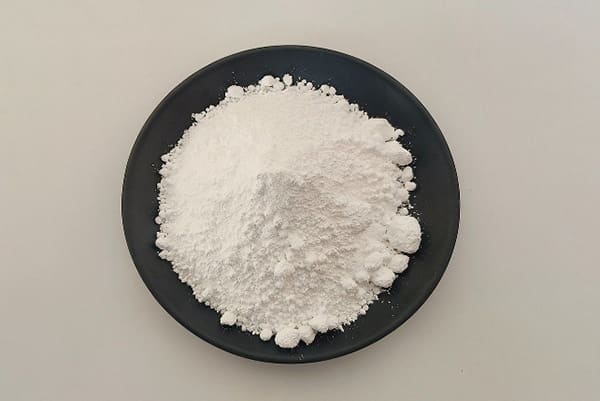

Aluminum oxide polishing powder is an essential material used across various industries, from metalworking to electronics, jewelry making, and even cosmetics. This versatile abrasive is prized for its hardness, durability, and ability to polish surfaces to a high sheen. But how is aluminum oxide polishing powder made, and what are the key steps in its production?

The Basics of Aluminum Oxide

Aluminum oxide, or alumina (Al2O3), is a chemical compound composed of aluminum and oxygen. It is naturally occurring in the form of corundum, a mineral that includes precious gemstones like sapphires and rubies. However, the aluminum oxide used in industrial applications is usually synthetically produced to ensure purity and consistency.

Raw Materials and Preparation

The production of aluminum oxide polishing powder begins with the extraction of aluminum from its primary ore, bauxite. Bauxite is rich in aluminum-bearing minerals and is the most common source of aluminum worldwide. The process starts with refining bauxite to obtain pure alumina through the Bayer process.

The Bayer Process

- Bauxite Crushing and Grinding: The bauxite ore is first crushed and then ground into a fine powder. This increases the surface area and makes the extraction of alumina more efficient.

- Digestion: The ground bauxite is then mixed with a hot solution of sodium hydroxide (caustic soda). Under high pressure and temperature, the sodium hydroxide reacts with the aluminum compounds in the bauxite, dissolving them into a soluble form, while impurities remain undissolved.

- Separation: The resulting mixture is then allowed to settle, and the undissolved impurities, known as red mud, are separated from the solution. The clear solution, containing dissolved alumina, is then decanted and filtered to remove any remaining impurities.

- Precipitation: The filtered solution is cooled, and aluminum hydroxide (Al(OH)3) begins to precipitate out. This aluminum hydroxide is then collected, washed, and dried.

- Calcination: The final step in the Bayer process involves heating the aluminum hydroxide to about 1,000–1,100°C in rotary kilns. This calcination process removes the water molecules, converting aluminum hydroxide into anhydrous aluminum oxide, or alumina.

Creating the Polishing Powder

Once the pure aluminum oxide is obtained, the next step is to process it into a fine powder suitable for polishing. This involves several additional steps:

- Grinding: The calcined aluminum oxide is ground into a fine powder using a series of mills. The goal is to achieve the desired particle size, which is critical for its effectiveness as a polishing agent. The finer the particles, the smoother the polish they produce.

- Classification: After grinding, the powder is classified into separate particles of different sizes. This is usually done using air classifiers or sieves. The classification ensures that the final product has uniform particle size distribution, which is essential for consistent polishing results.

- Purification: The powder may undergo additional purification processes to remove any remaining impurities. This can involve acid washing, magnetic separation, or other techniques to ensure that the aluminum oxide is of the highest purity, especially for applications that require ultra-fine finishes.

- Surface Treatment: Depending on its intended use, the aluminum oxide powder may be treated with surface agents to improve its performance. For example, coatings might be applied to enhance the powder’s ability to adhere to certain surfaces or to modify its abrasive properties.

- Packaging: Finally, the polished aluminum oxide powder is carefully packaged to protect it from contamination and moisture. It is typically packed in sealed containers or bags, ready for distribution to various industries.

Applications of Aluminum Oxide Polishing Powder

Aluminum oxide polishing powder is used in a wide range of applications. In the metalworking industry, it is used to polish and smooth metal surfaces, removing imperfections and creating a high-gloss finish. In the electronics industry, it plays a crucial role in the polishing of semiconductor wafers. Jewelers use it to polish precious metals and gemstones, bringing out their natural luster.

In addition to its industrial uses, aluminum oxide powder is also found in cosmetics, where it is used as a microdermabrasion agent in skincare products, helping to exfoliate and smooth the skin.

Conclusion

The production of aluminum oxide polishing powder involves several intricate steps, starting from the extraction of aluminum from bauxite through the Bayer process, followed by grinding, classification, purification, and surface treatment. The result is a highly effective abrasive material that is integral to many industries. Understanding the meticulous process behind its creation underscores the importance of precision and quality in the manufacturing of this versatile polishing agent.

Post time: 8 月-20-2024