The difference between Ultra AAC blocks and Eco AAC blocks lies primarily in the material composition, manufacturing processes, and specific applications, although both types fall under the category of Autoclaved Aerated Concrete (AAC), a lightweight and energy-efficient building material. Here’s a detailed comparison:

1. Material Composition:

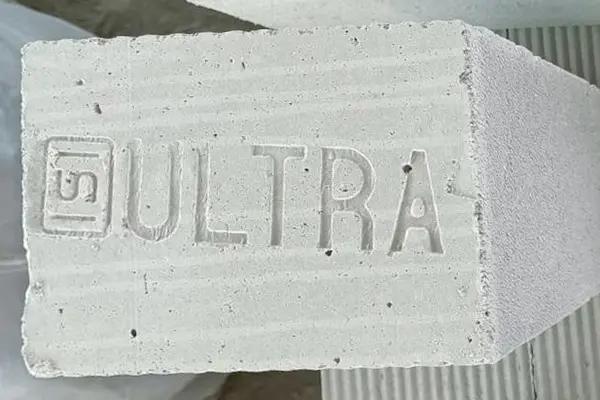

- Ultra AAC Block:

Ultra AAC blocks are often made with higher-grade raw materials or enhanced formulas that make them stronger, denser, and more durable than standard AAC blocks. This can include advanced binders, additives, or alternative aggregates that improve strength, insulation properties, or water resistance. - Eco AAC Block:

Eco AAC blocks are made with an emphasis on environmental sustainability. These blocks are typically produced using more eco-friendly raw materials, such as recycled aggregates, and may have lower energy consumption during the manufacturing process. Eco AAC blocks are designed to reduce the carbon footprint of production and promote green building practices.

2. Density and Strength:

- Ultra AAC Block:

Ultra AAC blocks tend to have higher density and compressive strength, making them suitable for load-bearing walls and structures that require greater structural integrity. - Eco AAC Block:

Eco AAC blocks are typically lighter in density compared to Ultra AAC blocks, although still strong enough for many non-load-bearing applications. They focus on energy efficiency and environmental benefits over maximum structural strength.

3. Thermal Insulation:

- Ultra AAC Block:

Ultra AAC blocks may offer superior thermal insulation due to their denser composition, which allows for better heat resistance and lower heat transfer. They are ideal for use in climates with extreme temperatures. - Eco AAC Block:

Eco AAC blocks also provide good thermal insulation properties but may be slightly less efficient than Ultra AAC blocks in extreme conditions due to their lower density. However, they still offer excellent energy efficiency and contribute to sustainable building practices.

4. Sustainability:

- Ultra AAC Block:

While Ultra AAC blocks are designed for strength and durability, they may not emphasize sustainability as much as Eco AAC blocks. The production of Ultra AAC blocks may require more energy or involve materials that aren’t as environmentally friendly. - Eco AAC Block:

Eco AAC blocks are specifically designed with the environment in mind. They often utilize recycled content, sustainable manufacturing practices, and more energy-efficient production methods to reduce overall environmental impact.

5. Cost:

- Ultra AAC Block:

Due to the higher quality raw materials and more robust manufacturing processes, Ultra AAC blocks are often more expensive than standard or Eco AAC blocks. - Eco AAC Block:

Eco AAC blocks may be more cost-effective, especially if the production involves recycled materials or lower energy consumption, which can lower production costs.

6. Applications:

- Ultra AAC Block:

Best used in construction projects that require enhanced structural performance, such as multi-story buildings, load-bearing walls, or areas with extreme weather conditions. Ultra AAC blocks may also be preferred for applications where durability and longevity are critical. - Eco AAC Block:

Ideal for low to mid-rise buildings, partition walls, and areas where sustainability and energy efficiency are prioritized. They are often used in green building projects or eco-friendly construction where reducing the environmental impact is a key goal.

Summary Table:

| Feature | Ultra AAC Block | Eco AAC Block |

|---|---|---|

| Material Composition | Higher-grade materials, additives for strength | Eco-friendly materials, recycled aggregates |

| Density | Higher density for stronger performance | Lower density, lightweight |

| Strength | Higher compressive strength, ideal for load-bearing | Sufficient strength for non-load-bearing use |

| Thermal Insulation | Excellent insulation, better heat resistance | Good insulation, slightly less efficient |

| Sustainability | Less emphasis on environmental impact | Focus on reducing carbon footprint |

| Cost | Higher cost due to premium materials | More cost-effective |

| Applications | High-load-bearing, extreme weather conditions | Green buildings, energy-efficient projects |

In summary:

- Ultra AAC Blocks are stronger, denser, and often used in applications where structural strength is critical.

- Eco AAC Blocks prioritize environmental sustainability, making them ideal for energy-efficient buildings and projects with a focus on reducing the carbon footprint.

If you have a specific project in mind, choosing between Ultra AAC and Eco AAC will depend on your balance between strength requirements and sustainability goals.

Post time: 11 月-14-2024